Foaming masterbatch is a functional additive specifically developed for plastic foaming applications, including EPE polyethylene foam, XPS polystyrene foam, and shoe sole materials. During the foaming process, it facilitates the formation of a stable, closed-cell structure with fine, uniform cells. This improves the overall foaming efficiency and enhances the consistency and quality of the final product.

Foaming Masterbatch Enables Fine and Uniform Cell Structures

Foaming masterbatch assists in the even distribution of gas during the foaming process, enabling the formation of fine, closed-cell structures.

This results in lighter, softer, and more resilient foam products with smoother surfaces—crucial for EPE foam, XPS insulation boards, and EVA shoe soles.

Foaming Masterbatch Supports Multiple Polymer Systems

Foaming masterbatch is compatible with various polymer systems such as LDPE, EVA, PP, and PS.

It enhances foaming efficiency across industries—from packaging and cushioning to footwear and thermal insulation.

Foaming Masterbatch Improves Cost Efficiency and Process Stability

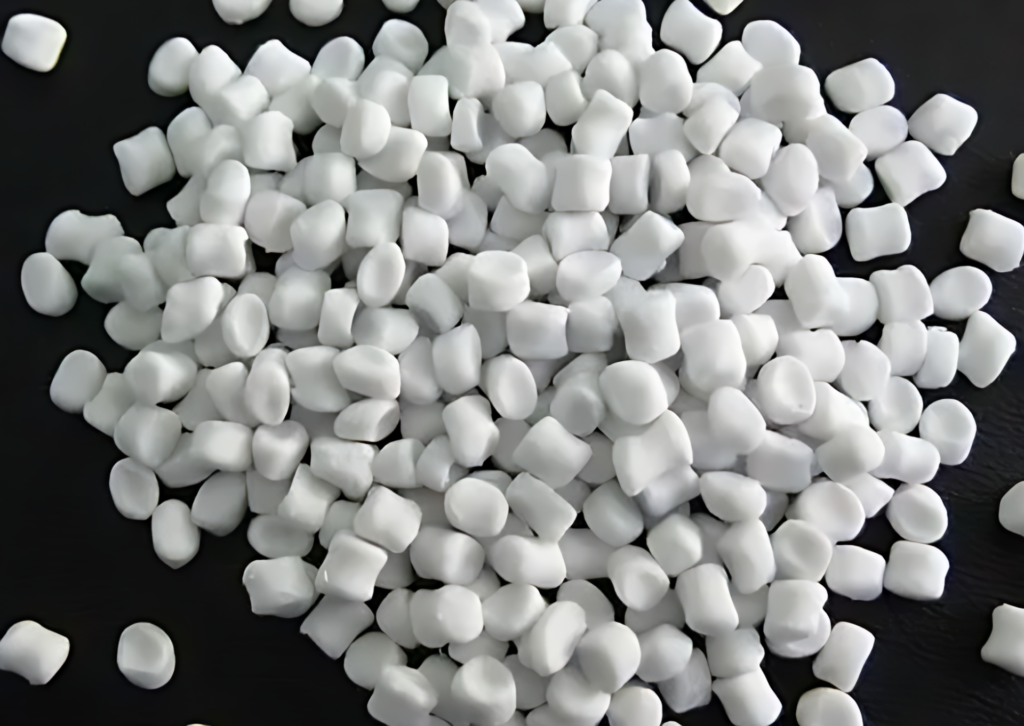

In pellet form, foaming masterbatch ensures easy dosing, reduces material waste, and eliminates dust.

Compared to traditional powder additives, it offers better consistency and safety in automated production environments.

Foaming Masterbatch Has Wide-Ranging Applications

Foaming masterbatch finds application in nearly all thermoplastic foams—from EPE and XPS to packaging foams and athletic shoe soles.

As the demand for lightweight and sustainable materials grows, it is becoming an indispensable part of modern foam manufacturing.

Conclusion

Foaming masterbatch is a key additive that enhances foaming efficiency and optimizes cell structure. As industries move toward lightweight and eco-friendly materials, this masterbatch plays an increasingly important role in modern foam production—delivering cleaner, more efficient, and more reliable processing results.