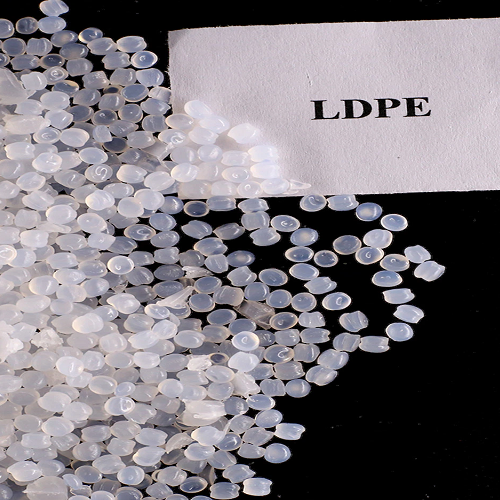

As a high-performance thermoplastic raw material,LDPE granules have excellent flexibility chemical resistance and processing adaptability, and are ideal for the production of lightweight and durable plastic products.LDPE products run the gamut from farm to squeeze containers and fill up every conceivable industry. But widespread use also lends itself to consideration of environmental stewardship, topics we’ll take up in this blog. Educating ourselves on LDPE applications and helps us to make informed decisions to reduce waste and encourage sustainability.

1. Material Advantages

Product advantages:High-purity granules, low impurities, ensuring processing stability and finished product consistency Meet environmental protection standards, recyclable and regenerated, helping customers achieve green production goals.Excellent chemical and moisture resistance.Good transparency and process ability.

2. Cutting-Edge Applications

Core application areas:

Packaging industry: blow molding/extrusion molding of food-grade cling film, plastic bags, bubble film, etc.;

Daily necessities manufacturing: soft bottle caps,detergent bottles,toy injection molding,Industry and agriculture: cable insulation cultural film, waterproof roll.

Lightweight films (packaging, agricultural),flexible containers, injection molds-valued for flexibility and moisture resistance.

3. Innovations and Future Trends in LDPE

The future of LDPE plastic is evolving with technical and sustainability developments. Technical innovations in the use of LDPE target reducing environmental effects while maintaining performance.

Bio-Based LDPE:Made from renewable resources like sugarcane to reduce the reliance on fossil fuels

Recycling of LDPE:LDPE is broken down through chemical recycling and mechanical recycling processes into quality recycled polymers for reuse.

Biodegradable Additives:Research on additives that make LDPE degrade faster is gaining popularity.

4. Conclusion

LDPE remains indispensable for flexible packaging. Low-density polyethylene (LDPE) is an inexpensive and durable plastic that is used in packaging,agriculture, and pharmaceutical industries. Provided it is treated appropriately, it is non biodegradable but recyclable, thus ideal for plastic manufacturing firms, but it has environment risks. While reducing the use of LDPE plastic products is the ultimate goal, there is a shift towards sustainable manufacturing through recycling procedures. The processing of LDPE products like LDPE film have various benefits, Recycling LDPE products and the use of recycled polymers is the shift that all industries require to play their part in contributing to a circular economy.