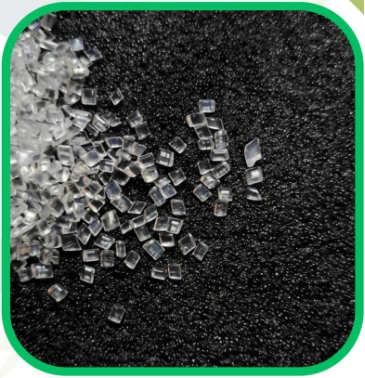

MASTERBATCH is a plastic particle with high concentration of pigment or additive. It is evenly mixed with base plastic to provide stable and uniform color and functional improvement for plastic products. It is widely used in plastic processing fields such as blow molding, injection molding, and extrusion.

1. Types & Technical Highlights

1)White MASTERBATCH:high hiding power, suitable for packaging, home appliance housing, medical devices, etc.

2)Black MASTERBATCH:high carbon black content.excellent UV resistance, widely used in automobiles, pipes cables, etc.

3)Color MASTERBATCH:provides bright and stable colors meet customer customization needs, suitable for all kinds of plastic products.

4)Functional MASTERBATCH:contains special function such as anti-static, anti-UV, fame retardant, toughening, etc.to improve the performance of plastic products

2.CHARACTERISTICS AND APPLICATIONS Of MASTERBATCH

1) TALCUM POWDER

Features:Forms closed-cell foam structure with fine and smooth cells /increases foaming ratio.

Application:EPE polyethylene foam, XPE polystyrene foam, sole foam, etc.

2)WHITE MASTERBATCH

Features:High cost-performance ratio /UV-resistant, anti-aging, and anti-yellowing.

Application:EPE,XPS, PE, PP, PA, PS and other plastic injection molding, extrusion, casting,film blowing, etc.

3)COLOR MASTERBATCH SERIES

Features:

Made with premium pigments, excellent coloring power, strong coverage, high-temperature resistance, anti-aging formula, and long-lasting color retention.

Application:PE, PP, PC, PS, ABS, PET and other plastics,suitable for injection molding, extrusion, wire drawing, foaming, film blowing, laminating casting, etc.

4)FOAMING-SPECIFIC BLACK MASTERBATCH

Features:

Does not reduce foaming ratio, no shrinkage,excellent hardness of foamed products, available for blackness level.

Application:Black MASTERBATCHE for foaming EPE, XPS, XPE, EVA foaming, etc

5)FOAMING-SPECIFIC MILKY MASTERBATCH

Features:

Does not reduce foaming ratio, no shrinkage,excellent hardness of foamed products, available for whiteness and hue.

Application: EPE,XPE,XPS, EVA foam, etc.

6)ANTISTATIC MASTERBATCH

Eliminates static during production or product use, no migration at high temperatures, non-greasy feel,improves mold release and flow dispersion, long-lasting effect. Does not affect internal foam pressure, achieving are in the range of 109 to 1010 ohms.

Application: Specially used for EPE, XPE, XPP and other foaming materials.

7)ANTI-BLOCKING & SLIP MASTERBATCH

Features:

Anti-blocking agents quickly migrate to the plastic surface, providing excellent opening and slip effects with low dosage and long-lasting performance.

Application:Suitable for PE, Pp films requiring fast excellent open ability, such as blown film, cast film, and bubble film.

8)FLAME RETARDANT MASTERBATCH

Features:

Complies with EU environmental standards free from PBB and PBDE, does not affect product performance. Some products achieve self-extinguishing with a dosage of 3%~5%.

Application:Suitable for extrusion,injection molding, foaming,etc.of PE, PP, PC, ABS, PS, EVA, etc.

9)ANTI-AGING MASTERBATCH

Features:

Made with high-quality imported raw materials,long-lasting anti-aging effect, low dosage, and high cost-performance ratio.

Application:Suitable for PE, PP, PA, ABS, PET, PS, EVA and other products to resist aging, UV, fading, yellowing,brittle cracking, and significantly increase the service life of products

10)TOUGHENING MASTERBATCH SERIES

Features:

Improves product toughness by 30%~60%,effectively enhances impact resistance,recommended dosage 4%~6%, with about 50% filler toughening additives.

Application:Suitable for most PE, PO, PP, PA, ABS, etc.Including extrusion, injection molding, blow molding, etc.

3. Future Outlook

Smart MASTERBATCHE : additives for real-time quality monitoring.

Bio-Based Carriers : PLA/PHA carriers for films.

4. Conclusion

Functional MASTERBATCHE are the backbone of next-gen plastics. Partner with to unlock tailored solutions for your industry.